Problem Overview

The Sea Perch kit which the Navy

provides for its Sea Perch competition makes use of very small, low powered,

low cost motors to act as thrusters on an underwater submersible to be used in

a pool. These motors fall apart

and break very easily. The goal of

this project is to modify the propulsion system and chassis of the Sea Perch

kit so it can be used in rivers.

Design Constraints

Considering that we are designing

this project ourselves, there are not many constraints in terms of what we can

and cannot use. The main

constraint is we lack funding and therefore would like to keep this as low cost

as possible so perhaps Sea Perch can implement it.

The other thing that has to be

taken into account is there is a current in a river but not in a pool. Therefore, the motors we ultimately use

must provide more thrust than the Sea Perch motors. Furthermore, we need to take the size of the motor into

account when deciding on the shape and size of the chassis.

Pre-Existing Solutions

There are many pre-existing

solutions to this type of problem.

However, we are trying to keep the solutions as cost-effective as

possible in order that the Sea Perch kit might be redesigned within

approximately the same current cost parameters, but instead implement the new

changes which we propose.

One of the problems of the Sea

Perch ROV is they are not hydrodynamic.

The typical ROV is in the shape of a square with three motors

attached. If the shape of the

chassis of the submersible is changed to be flatter, the submersible may work

better. There are many different shapes of submersibles which have been

explored. In general, the most

hydrodynamic submersibles were the most effective. These submersibles were typically flat or triangular in

shape. A team of Darmstadt

researcher’s built a robotic fish that emulates the movement of a fish using

waterproof actuators. The shape of

the fish is a very hydrodynamic shape.

While this approach is probably the best option for an efficient

hydrodynamic submersible, it is not within our cost or time constraints.

Another problem with the Sea Perch

submersibles is they do not use high quality motors. Many different motors have been used on underwater

submersibles to increase thrust.

However, in Sea Perch, no alternative is offered. Furthermore, the propellers on the

existing Sea Perch motors fall off.

Some submersibles use a special water resistant glue to hold the

propellers on to the motor’s shaft.

Other submersibles actually have the propellers melted on to the motor’s

shaft.

Going from a pool to a river is

also a problem caused by current which many submersibles have already

handled. The ACE-ROV created by a

team of students from Dalhousie University uses 1100 GPH bilge pump motors with

custom built propellers. They are

placed in a way that allows for strafing from side to side and forward and

backward, up and down. Obviously,

using higher-powered motors for thrust is one way of solving this problem. Furthermore, changing motor placement

can provide more thrust.

Because there are so many ways of

solving each of these problems and because there are multiple problems

occurring at once, it is almost impossible to list all of the solutions.

Design Goal

| Figure 1: 12V 350 GPH Liquid Pump |

|

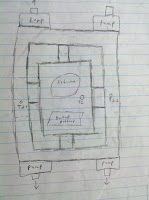

| Figure 2: Schematic of Proposed Chassis and Motor Placement on submersible |

We

are using two of the motors for a buoyancy and ballast system that will raise

and lower the submersible.

We

are also attaching a camera for purposes of orientation and ease of

driving. The camera we will attach

is a low cost underwater camera which can be purchased at Cabela’s, a sporting

goods store.

We

are making a tether for our robot as well. We are also including a rope in that tether so that if

something goes wrong, the submersible can easily be pulled out of the water without directly pulling on the wiring.

Project Deliverables and Schedule

Week

|

Item

|

Description

|

1

|

Blog and Brainstorm

|

-Set up the blog with

the Home Page and Design Ideas Page.

-Use the Design Ideas

page to store and present brainstormed ideas.

|

2

|

Finalize Design

|

-Go through

brainstormed ideas and decide which ideas are best.

-Have a general idea

of the placement of motors.

-Have a general idea

of the chassis shape and size.

-Have a general idea

of how the robot will be wired and programmed.

|

3

|

Decide what needs to

be ordered and receive Sea Perch Kit.

Set up Home Depot/Lowes date.

Finish finalizing the design.

|

-Order Motors.

-Receive Sea Perch

Kit. Decide what exactly will be

used from kit.

-Decide what else

needs to be purchased and/or brought in from home.

-Set up date to go to

Home Depot or Lowes together.

-Have a solid design.

|

4

|

Build Chassis and

Thrust System

|

-Build chassis and

install motors.

|

5

|

Build

Buoyancy/Ballast System

|

-Build

buoyancy/ballast system.

|

6

|

Wiring/Electrical

|

-Wire the

submersible.

-Install and test the

camera.

|

7

|

Test Submersible in a

Pool and Make Adjustments

|

-Test submersible in

Drexel’s pool.

-Make necessary

adjustments after testing.

|

8

|

Test Submersible in

the River and Make Adjustments

|

-Test submersible in

the river.

-Make necessary

adjustments.

|

9

|

Final Adjustments and

Final Paper and Presentation Preparation

|

-Make any minor final

adjustments to the submersible.

-Complete the final

paper.

-Complete the

presentation.

-Finish the Blog.

|

10

|

Final Presentation

|

-Give final

presentation.

|

Cost Analysis

Quantity

|

Item

|

Cost Per Unit

|

Total Cost

|

Comments

|

6

|

Liquid Pump – 350

GPH(12V)

|

$14.95 + S&H

|

$89.70

+

$13.18 (S&H)

$102.88

|

http://www.sparkfun.com/products/10455

|

1

|

Sea Perch Kit

|

$0

|

$0

|

Donated by Navy

|

1

|

Cabela’s Underwater

Camera

|

$99.99 + S&H

|

$99.99 + S&H

|

http://www.cabelas.com

|

Varies

|

PVC

|

Price Varies

|

$20-$30Cabel

|

The size of the PVC

and cost of the PVC vary. It

depends upon what is included in the Sea Perch kit and how large the ballast

tank will be.

|

Varies

|

Wire

|

Price Varies

|

$20-$30

|

The amount of wire

and gauge of wire depends upon the controller and motors, both of which we

have not received yet. Also,

depends upon the length of the tether.

|

1

|

Gorilla PVC Cement R04000 4oz Clear

PVC Prima Glue

|

$5.00

|

$5.00

|

http://www.google.com/products/catalog?q=pvc+glue&hl=en&safe=off&client=firefox-a&hs=oFP&rls=org.mozilla%3Aen-US%3Aofficial&prmd=imvns&bav=on.2%2Cor.r_gc.r_pw.r_qf.%2Ccf.osb&um=1&ie=UTF-8&tbm=shop&cid=17554615529151053364&sa=X&ei=EMiQT-2XPKqX6QHZ8tiMBA&ved=0CJ4BEPICMAM

|

No comments:

Post a Comment